Hotline:

18917685339

18917685337

Set r & d, production, business, service as

one of the non-standard equipment, machine accessories and hardware power tools

production service providers

INDUSTRY AND TECHNOLOGY

ABOUT US

I.Characteristics of chamfering machine:

Our company's handheld chamfering machine is Bosch imported from Germany, with stable performance and long service life.

The cutting head part is developed and designed by our company by ourselves.

Table chamfering machine adopts end milling, high motor speed, bright workpiece processing. The motor is connected with the tool head through the spindle and coupling, which has long service life and high precision.

(1)Notes for use of portable chamfering machine:

Before use, check whether the blade is compact and intact.

When working, should start the switch to make the machine idle, and then contact the workpiece, so as not to burn out the motor due to the starting load.

After working continuously for 30 minutes, the machine should be shut down for a few minutes to avoid overheating and burning out of the motor.

Before making any repairs to the machine, be sure to unplug the power supply to ensure safe operation.

A professional electrician checks the brush once a month to see if it needs to be replaced, while cleaning the motor with compressed air for dust and checking for loose screws.

Always check whether the tool particles are worn and need to be replaced. The power should be cut off when the blade is replaced, and the equipment should be cleaned and maintained at the same time.

In case of abnormal conditions, the machine should be immediately cut off the power supply, notify the supplier or by professional personnel inspection, maintenance.

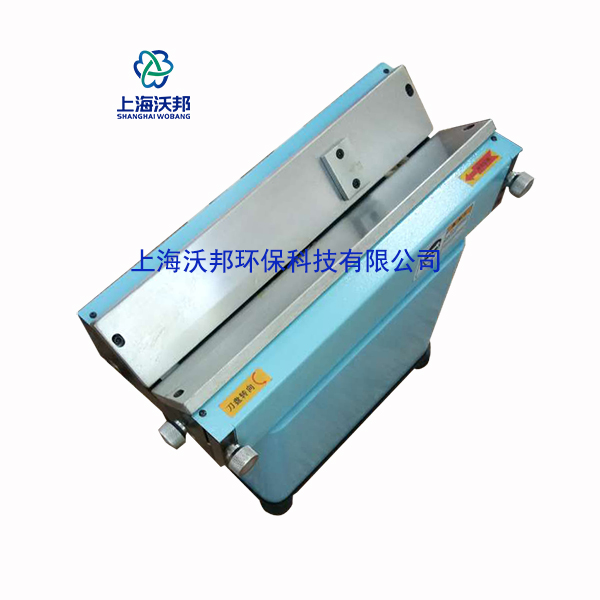

(2)Matters needing attention in the use of desktop chamfering machine:

Pay attention to the turn of the motor when connecting the power supply, the correct direction is counterclockwise.

Check whether some fasteners are loose before use, and then adjust the chamfering size with the test tool block.

When working, pay attention to the cutting direction of the workpiece, do not make a mistake.

II. Characteristics of oil-water separator:

Our belt type oil-water separator with acid, alkali, oil, high temperature of the high quality oil absorption (polymers) skills, its structure is compact, small footprint, suitable for the separation of the cutting fluid pollution, such as aluminum cutting, and other granular impurities, can choose disc separator, the oil absorption plate is made of tool steel or PT plate to filtering device is installed in place of discharge of oil, separation, cleaner, and long service life.

(1)Installation and use of oil-water separator and matters needing attention

The body should be installed horizontally. The oil absorption belt should not be in contact with the cooling tank cap or other articles.

The submerged slave wheel is preferred for the liquid level.

If the driving wheel turns and the oil suction belt does not move, please check whether the oil suction belt deviates or gets stuck.

Oil discharge channels should be cleaned regularly to prevent blockage, so as not to affect the use effect.

Pay attention to the voltage.

III. Installation and use of magnetic separator and matters needing attention:

1.Select according to liquid flow.

2.Pay attention to electric voltage and motor steering.

3.If the used magnetic separator is out of service for many days, iron filings on the scraper of the magnetic separator should be cleaned before starting to prevent iron filings from bonding to affect the normal rotation of the magnetic hub, so as to avoid motor burning.